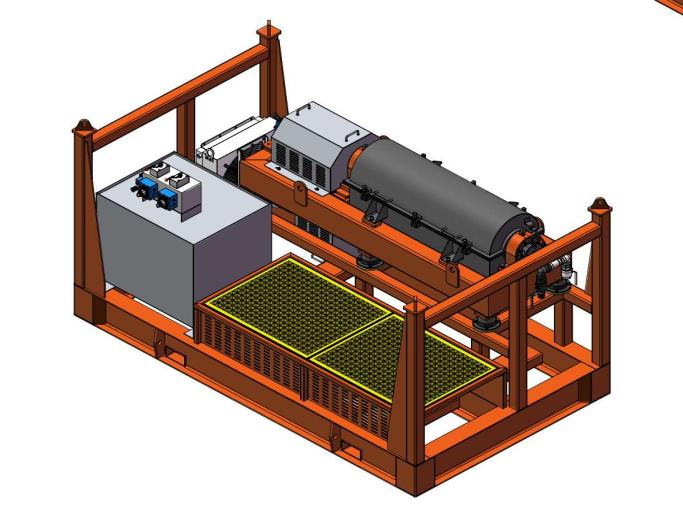

At KESMI, we understand the reliable performance and efficient operation are essential in separation processing. That’s why we’ve engineered the KSLW Series Decanter Centrifuge – a hydraulic driven solution that combines durability, compact design, and affordability, making it an ideal choice for mining, oil and gas, industrial sludge and wastewater treatment.

Working Principle

- Feeding Stage: The drilling fluid or process liquid enters the decanter centrifuge through an inlet.

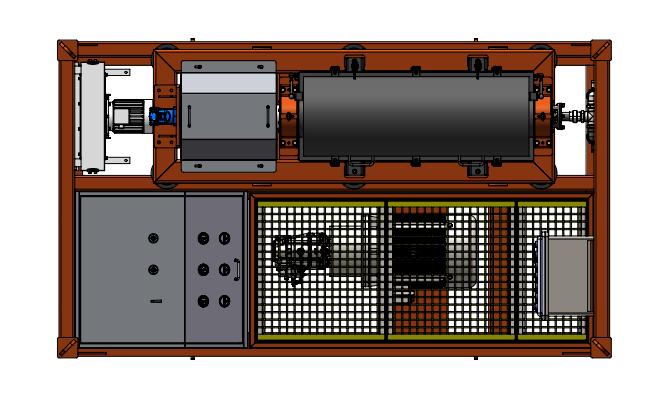

- Centrifugal Separation: Inside the centrifuge bowl, the fluid mixture is subjected to high-speed centrifugal force generated by the hydraulic motor. The centrifugal force separates the 7–15 micron solids from the liquid, with heavier solids moving outward to the bowl’s wall, while the liquid is pushed towards the center.

- Solids Discharge: The separated solids (such as drill cuttings or sludge) are continuously discharged from the centrifuge into the tank, ready for disposal or further processing, while preventing materials from falling to the ground, minimizing environmental pollution.

- Clean Fluid Returns to the Circulatory System: The clean fluid separated from the solids, and ready to return to the system for reuse or further processing through the “closed loop”, zero wastewater discharge.

Key Advantages

- Hydraulic Power for Simplicity and Efficiency: One of the standout features the hydraulic drive technology, offers energy efficiency and ease of operation. Hydraulic unit delivers stable pressure (20–25 MPa) for bowl and screw, ensuring a more sustainable and cost-effective solution than traditional systems.

- Compact and Ease of Mobility Design: Its small footprint makes it perfect for the limited space, also can be easily transported or installed in various settings.

- Affordable and Cost-Effective: KESMI offers a budget-friendly solution without compromising on quality or durability for our clients.

- Reliable Performance: Built with high-quality components, including the pumps, motors and main rotation parts, especially for the pumps and motors tested for 2,000+ hours, screw shaft and impeller are all made from SS304, SS316 and duplex SS2205 for optional, screw blades protected by tungsten carbide alloy tiles, bowl cylindrical and conical section made from duplex SS2205. It can perform efficiently in demanding environments, guarantees continuous, reliable operation and 30% longer lifespan.

- Energy-Efficient: The hydraulic drive system provides energy-efficient performance that reduces overall energy consumption.

- Versatile Applications: This series is highly versatile, flow control valves enable 0–3,200 RPM stepless speed adjustment, adapting to varying conditions, ensuring adaptability in mining, drilling, wastewater treatment, or other industrial processes.

- Easy to Maintenance: No fragile electronics, the hydraulic drive makes easier to maintain. With fewer moving parts and no complex electrical control systems, KSLW series keeps downtime to a minimum.

KESMI KSLW-FHD Decanter Centrifuge is an affordable, reliable, and compact solution for liquid-solid separation. Powered by a hydraulic drive system, the decanter offers exceptional energy efficiency, ease of maintenance, and consistent performance. If you’re looking for a decanter centrifuge that is reliable, affordable, and powered by hydraulic technology, KSLW-FHD Series is the right solution for your business.

We deliver no-nonsense, durable solutions—not hype.